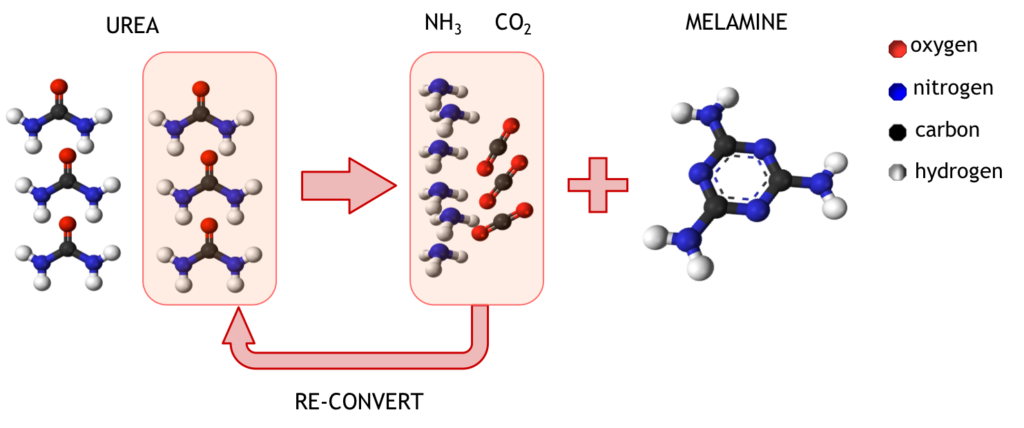

From Urea to Euromel® Melamine

A prime investment opportunity

Going downstream is a natural option for any player in the nitrogen-based industry.

Going downstream is a natural option for any player in the nitrogen-based industry.

Producing melamine is an opportunity for generating higher profits and, at the same time, hedging the seasonal fluctuations of the urea market.

Producing Euromel®, a top quality melamine whose average selling price is 4-6 times the feedstock price, means immediate access within a global network of highly reputed producers using Euromel® Melamine Technology and reduces the investor’s costs/risks associated to entering a new market.

Add-on chemicals (that generate safety concerns, pollution and additional OPEX and CAPEX) are never being used in this process.

Depending on the set-up, a Euromel® melamine plant can be run either on urea or ammonia. Therefore one, or the other, is the only raw material consumed.

Whatever the technology used for the upstream urea unit, Euromel® Melamine Process ensures a net urea consumption of 1.428 ton per ton of melamine. Since the urea feedstock is by far the major cost item in the composition of melamine plants OPEX, its minimization is extremely important.

The exhibits below show three modes by which a Euromel® Melamine Plant can be connected to a urea plant: